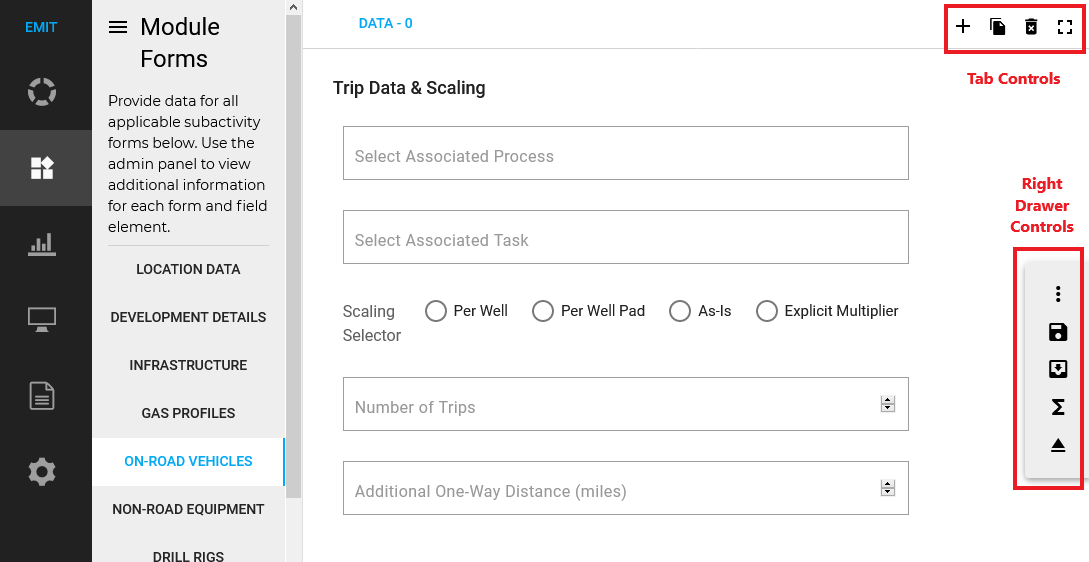

Data for some of the module forms are rendered in EMIT as 'array' types, meaning that users can enter multiple sets of data on these module forms to fully characterize or describe describe the activity or process. For example, the On-Road Vehicles Module Form allows only one vehicle class to be selected. If a project includes activity from both heavy-duty diesel trucks and light duty gasoline vehicles, then the user would define the activity for each of these vehicle types on a separate tab. Note that not all module forms support multiple tabs. For the module forms that do support multiple tabs, the upper right corner of the main screen includes tab controls, as shown in Figure 2. Labels for each tab are listed on the top left of the data entry screen, with the active tab in blue font.

The actions associated with clicking on each of these tab control icons is described below.

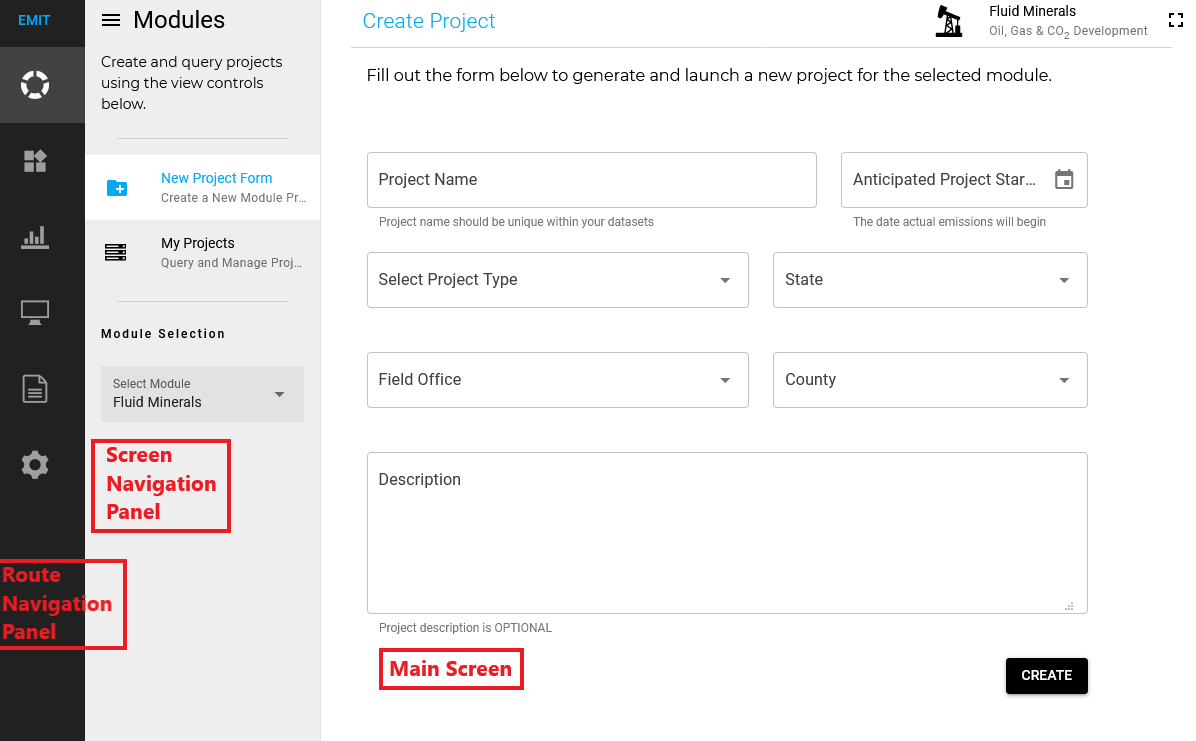

The first step in using EMIT is to create a new project. Projects are created and loaded from the Modules route of EMIT. When EMIT is first opened, the Modules route is shown. To create a new project, the user must select New Project Form from the top of the screen navigation panel as well as the appropriate EMIT module at the bottom of the screen navigation panel from the Module Selection dropdown menu, which includes the following eight modules:

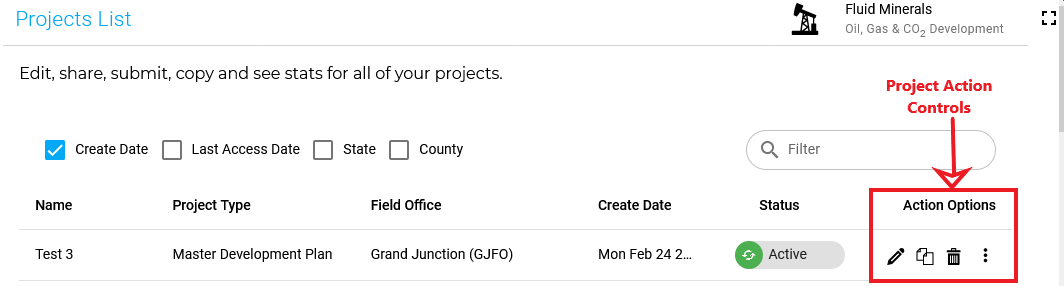

Once a project has been created in the EMIT Tool, it must be loaded before project parameters can be entered and emissions calculated for the project. From the Modules route, select My Projects in the navigation screen. All existing projects of the selected module type for the user will be listed in the main screen. Available project actions are described in the Project Actions section. Data for a loaded project can be entered by selecting the Module Forms route in EMIT.

In the main screen, the user then enters information pertinent to the project to be modeled. All fields other than Description must be populated for a new project to be created. Filling in the Description field is optional, but strongly recommended, particularly if the project information and emissions will be submitted to BLM. The fields included in this menu are shown below.

Once all fields are populated accordingly, the user must click the CREATE button in the bottom right corner of the tool. If the project has been successfully created, a success message will briefly appear at the top of the screen (SUCCESS: Project Created). If no other project is currently loaded, the user will automatically be taken to the Module Forms route tab.

The steps needed to model a hypothetical simple project in EMIT that involves only travel by on-road vehicles are shown below.

The Module Forms route provides the data screens where the user enters the specific data that define their project. The Module Forms specific to the selected Module are listed in the screen navigation panel. Clicking on the name of any of these Module Forms takes the user to that portion of the input. Each Module Form contains the entries for the user to input the data needed to identify and calculate emissions for a related group of activities or equipment.

Users can explore the Module Forms associated with each loaded module by clicking on the specific list item in the Module Forms route of EMIT. These forms should be completed in order from top to bottom. The activities in the various forms build upon each other and users may experience unexpected results if certain form data are missing from a previous form in the list (for example, emissions calculations may not return a valid result).

After completing data entry on any of the module forms, the user can click on the calculations icon in the Right Drawer Controls, as shown in Figure 3, to verify that all of the necessary data needed to make emissions calculations for that particular sub-activity / equipment type have been entered. The parameters and values listed when the calculations icon is clicked reflect either user-entered data or a calculated value that EMIT has generated based on the entered data. These intermediate parameters are generally need for one or more emissions calculations in EMIT. EMIT provides the user with parameter dependency information for all the displayed calculated values and informs a user of which data inputs need to have entered in order for that variable to be properly calculated by EMIT. When the user clicks on one of the calculated parameters shown, EMIT will display a list of required inputs and indicates which Module Forms those inputs are entered on. A red X in front of the input indicates that the user has not entered valid data for that input, while a green check mark indicates that the input has a valid entry.

Use this module to estimate emissions from oil, gas, and carbon dioxide (CO2) mineral development. This module estimates emissions from both construction and production related activities and provides delineation for fee/fed wells (where only a portion of the production is from federal mineral estate). Of all the emissions modules in EMIT, this one has by far the most required user inputs simply due to the complex nature of the industry.

Project information and data needed to calculate emissions for fluid minerals projects should be entered in the following EMIT Module Forms:

Once project data has been entered on the module forms for a project, the resulting emissions as calculated by EMIT are presented in the main screen. When the Emissions module is selected, the screen navigation panel provides several view selectors for reviewing project emissions associated with the loaded project. The user can select between three configurations for viewing emissions results: Table, Pie Chart, or Line Chart. Additionally, on the screen navigation panel, the user can choose to view emissions from either all criteria and hazardous pollutants (PM10, PM2,5, VOC, NOx, CO, SO2, and HAPs) or from greenhouse gases (CO2, CH4, N2O, and CO2e), by clicking the button in front of one of these options. Finally, the screen navigation panel provides a checkbox for selecting to display only Federal emissions (i.e., just the portion of emissions associated with Federal minerals, as identified on the Development Details module form in the Percent Federal Mineral data entry).

Emissions can be displayed in one of three ways:

By selecting the Modeling icon from the route navigation panel, the user is provided with tools for developing input files for dispersion modeling. Four selections can be made from the Modeling screen navigation panel.

The Reports screen navigation panel provides the user with access to two different types of automated reports for summarizing the project data. The first includes module fields and project data reports, which provide the user with summary information about the project data needed for EMIT or entered by the user in EMIT. The second includes general conformity reports which evaluate the resulting project emissions in comparison to general conformity requirements. Both of these report types are discussed below.

Module Fields & Project Data:

This section provides details on the emission calculations within EMIT. Variables that are entered by the user are noted, along with the corresponding module and data field where the variable should be entered.

In order to estimate emissions for the entire duration and scope of the project, a number of modules include an entry for the user to indicate whether provided data should be scaled. This entry appears as follows:

The following module forms include this scaling selector:

The user must select one of the scaling selector options, or emissions that are calculated with this scalar will not be calculated. The resulting scalar is determined as follows, based on the user’s selection:

This section describes how EMIT estimates fugitive dust emissions from traffic on unpaved public and industrial roads. The calculations are for particulate matter emissions only and do not include the associated tailpipe emissions from vehicle fuel combustion which are calculated separately as documented in the On-Road Vehicle Exhaust and Evaporative Emissions section. The emission calculations are based on the methodologies outlined in EPA AP-42, Volume I, Chapter 13.2.2. As vehicles travel on unpaved surfaces, particles are created (via pulverization), lifted and dropped by the wheels. These particles can become entrained in the vehicle's turbulent wake as it passes and can then be transported to varying degrees away from the point of origin.

Fugitive dust emissions factors are estimated via engineering equations (developed from empirical data analysis) for each specific pollutant being analyzed (PM10 and PM2.5). Emission factors for fugitive road dust for travel on public roads are calculated using Equation 1 and emission factors for fugitive dust from travel on industrial roads are calculated using Equation 2.

The general equation for calculating unpaved road fugitive dust is shown below in Equation 5. EMIT applies this calculation to each vehicle class provided by the user (to provide task / temporal speciation) and the individual results are then summed to calculate the total unpaved road fugitive dust emissions for the project.

This section describes how EMIT estimates general heavy construction emissions due to earthwork for a construction project. This includes fugitive dust particulate matter emissions only and does not include tailpipe emissions from fuel combustion, which are calculated separately. Emission calculations for heavy equipment construction operations are based on AP-42, Volume I, Chapter 13.2.3 and 13.2.4 methodology. Chapter 13.2.3 provides the base emission factor used for the fugitive dust from heavy construction operations in terms of total suspended particulate (TSP) while Chapter 13.2.4 provides the particle size multipliers that are used to convert the TSP emission factor to PM10 and PM2.5 emission factors.

Potential emissions associated with fugitive dust generated from land disturbance and associated wind erosion are based on an engineering calculation using emissions factors for heavy construction and user input to quantify the amount of land area disturbed by these operations and the duration of the disturbance. Fugitive dust emissions associated with heavy construction operations at a well pad include land disturbances that occur in creating the pad, building access roads where needed, and laying pipeline where appropriate. Emissions are calculated using Equation 6

Fluid Minerals: Oil, Gas, and CO2 Development

Solid Minerals: Coal, Locatable, and Saleable Mineral Mining

Forestry: Timber and Wood Products

Grazing: Cattle, Sheep, Bison, and Horse Allotments

Travel Management: Route and OHV Management

Right of Ways: Access, Power, and Pipeline Emissions

Vegetation Management: Prescribed Fire, Mechanical, and Chemical Treatments

Renewable Energy: Wind and Solar Power Development